EJ Talik - Craftworks Fab - S4. Ep40

Listen Here!

Hand Built Hotrods

Hand built, there’s a lack of that going around these days, new manufacturing processes have made goods cheaper and more reliable. But there’s something beautiful about hand built, its human, its something you can relate to. In every sense of the phrase “hand built",” EJ Talik is putting out some of the best hand built hotrods on the streets in America. Trained by fire he has learned the old school ways of swapping metal and has a resume that includes Riddler and Good Guys winning hotrods. His one man shop outside of Pittsburgh PA includes simple tools and a lot of man power. No big power hammers, no CNC machines, just EJ, basic metal shaping tools and a sore shoulder that could tell a story.

Tucked away in Coraoplis, PA right outside of Pittsburgh, is a converted gas station where EJ spends most of his days banging on metal inside Craftworks Fab. He was inspired by Jesse James and the show Monster Garage who he still to this day idolizes. His start was completely by accident and like many went to a local technical school and learned the basics of mechanics. After spending nine months at Wyotech, he fully intended on being a dealer mechanic however after a local dealership kept pushing his start date back he passed a local hotrod shop and decided to drop off a resume. After taking a quick tour and lying his way in the door, he got a job doing metal fabrication. Again, EJ was trained as a mechanic not a fabricator. With the “fake it until you make it” mentality he soaked up how to use all of the machinery with the help of a fellow fabricator Josh Hart. He became so good, the cars in the pictures today are some of the daily creations from a “mechanic.”

EJ’s first hotrod was a 71 Ford Torino wagon that hadn’t been run in 10 years. At 19 and with zero money, he did what we’ve all done, cut the springs, painted a few parts and got it on the road. The first big bump EJ hit in the car ignited and explosion of rust from under the dash that almost blinded him. He did however manage to put a few thousand miles on the car but had to sell it after he met his wife and had a kid. This was his indoctrination into why he couldn’t half ass stuff.

Riddler cars are something that are commissioned by “crazy people,” who want the job to be done right. EJ is all about, ”doing it right the first time.” He explained, “I have turned down work because some body will show up and say they only have x amount to spend…they will want to cut all of these corners and I’ll have to tell them I’m sorry I can’t do that for you.” He hates cutting corners and, “It’ll always come back to bite you in the ass.” This dedication to quality shows in everything that he puts out. Whether it be a chopped body or a simple cover for a radiator, everything has a purpose on a build that not only has to look good but perform. We spoke about the engineering that goes into these cars and parts that can’t simply look cool but also function.

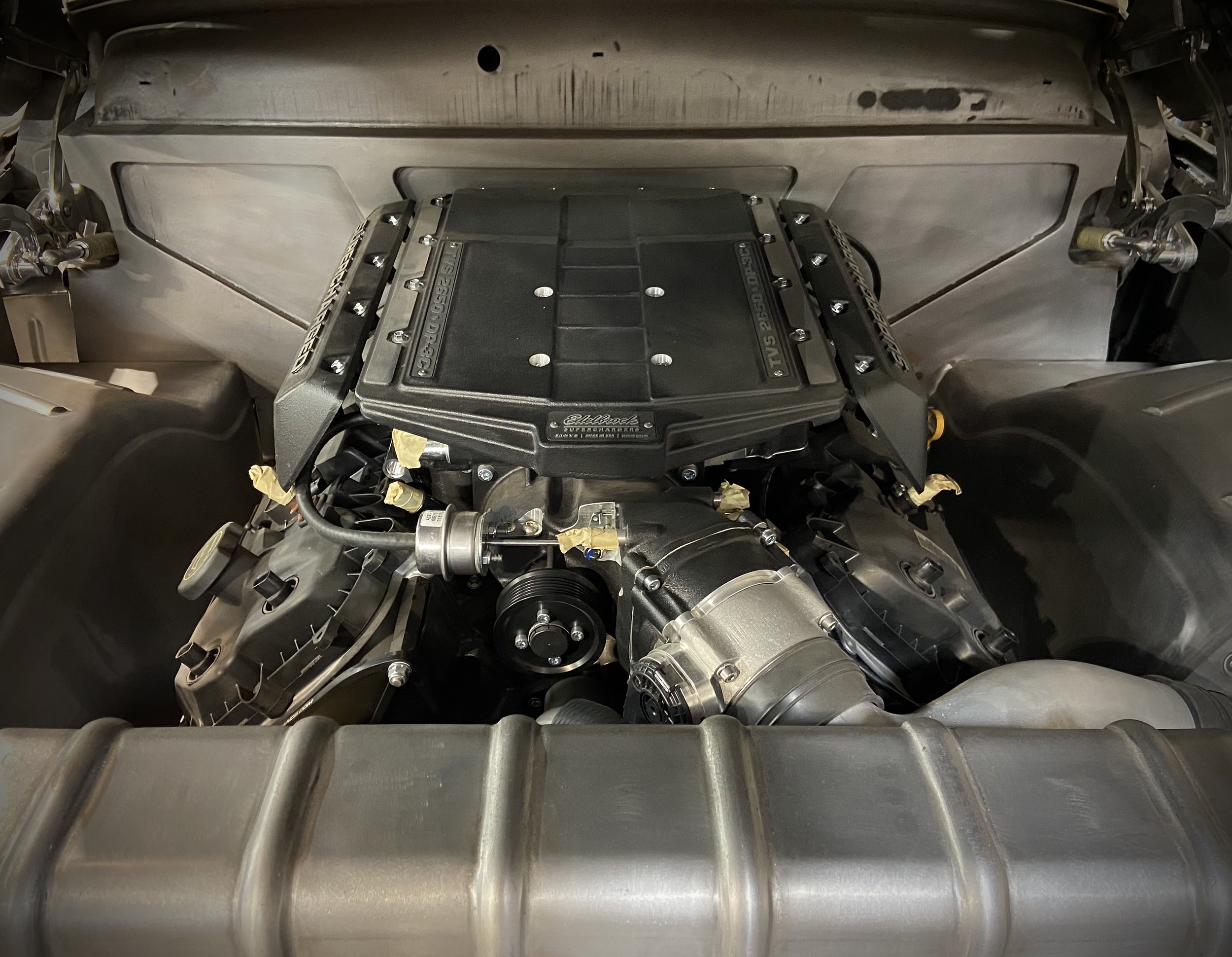

Unlike some of the show cars you’ve probably seen EJ likes to build cars that actually can perform and drive under all conditions. While he’s been involved in high end hotrods he really enjoys cars you can, “go out and beat the sh$% out of.” This is where the engineering part comes in to play. Not classically trained in engineering, building car after car has taught EJ the right and wrong way to properly make cars perform at a high level. With something like an engine bay the whole thing needs to be thought through before any metal is cut. All of the modern components need to fit all while simple tasks like engine heat escaping and cooling need to be taken into consideration. EJ pans 10-15 steps ahead before he starts any one piece. In the instance of the floors, EJ takes how the exhaust will be routed, wiring, fuel, monster transmissions and any other components that could effect these or other unrelated parts into consideration.

EJ’s philosophy for building cars is similar to all of the greats, “keeping true to the car…less is more” however making modifications that you need to hunt for while flowing with the car. “Pick the thing you’re best at and stick with it,” he explained. He would much rather stick to the body and metal work and leave another artisan to the paint, interior and chassis. The trend has come back to more of a traditional look from big spoilers, splitters and all types of mods were just plastered on the car. Cars that EJ has been a part of between all of the shops he’s worked for have tried to keep it simple while ensuring the car still looks like what its was intended to be.

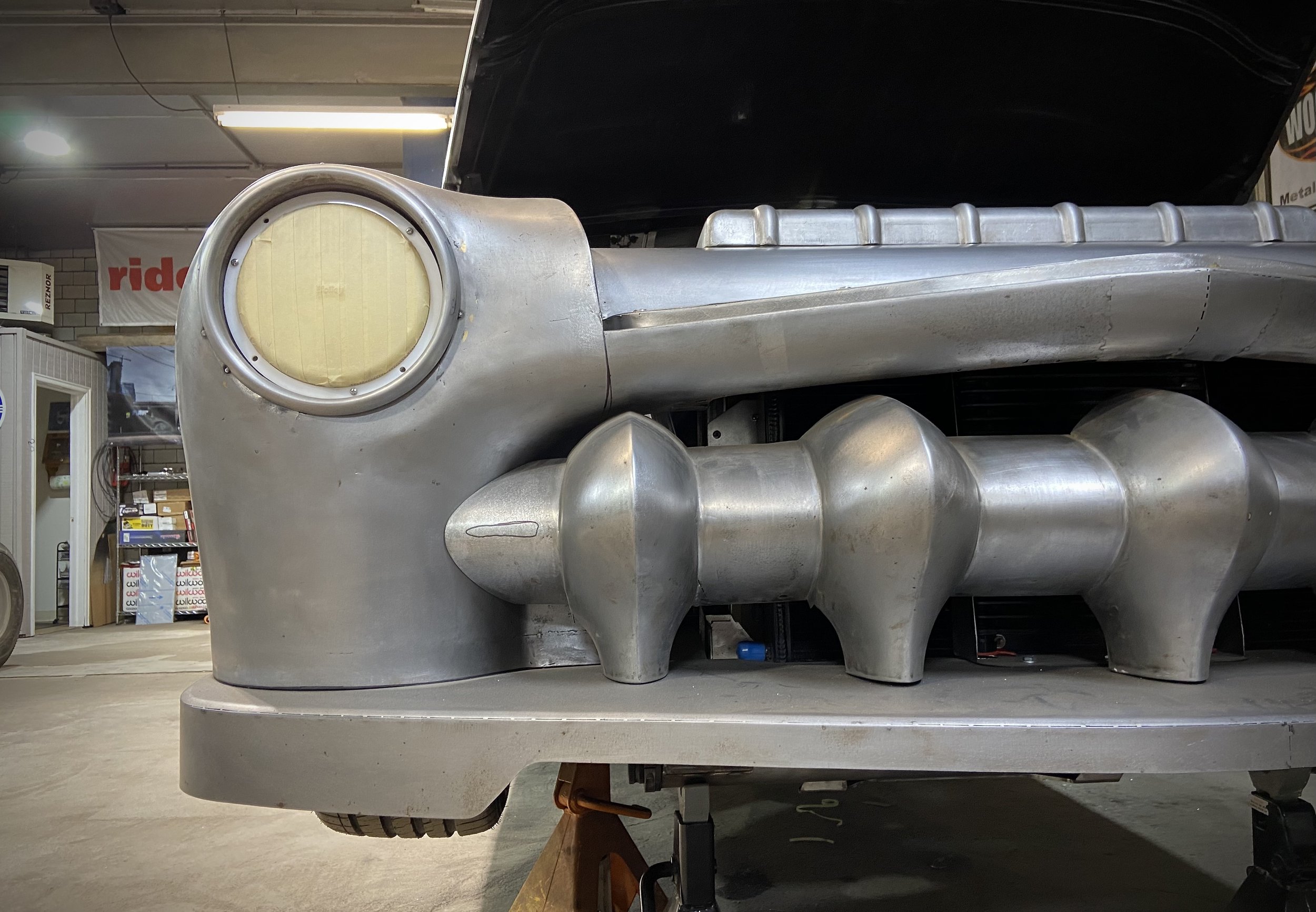

During the podcast we mainly spoke about the 1950 Mercury he’s been working on for a few years. The car came to EJ looking like it was customized back in the 70s sitting on a body cart with no chassis and full of rust and epoxy. EJ immediately went to the best in the business Roadster Shop to get a full fast track chassis on air. After ordering the chassis EJ braced the inside, gutted the entire car and started building out the structure. The roof was the worst as whoever did the original chop performed so bad entire back half of the car needed to be cut off. EJ then made his own roof, eliminating the B pillar, that now flows beautifully into the rear of the car that gives it the open air feel. While the image of a 49-51 Merc comes to mind when talking about custom hotrods, EJ quickly found out there aren’t a lot of original parts out there. EJ handmade all of the patches for the body, doors, rockers, bottom half of the fender, window tracks, trims and the list goes on.

Like I mentioned earlier, EJ builds cars to perform and drive and this one is no different. That aforementioned Roadster Shop chassis will be set up as a pro touring style suspension which will have a rake from front to back instead of the traditional rear sag. The motor is a supercharged Aluminator Ford Coyote motor that will eventually make 700-800hp. Everything from the firewall forward in the engine bay now has the EJ signature fabricated look. Trying to get away from the bead rolled pieces EJ is now introducing recessed panels giving the pieces depth. The entire engine bay will be wired and plumbed so you won’t see a single wire or hose. The final design will resemble something that could have come out of 1950 while incorporating all modern components. If you’re wondering, there’s about 150 hours in just the engine bay as it sits right now.

There will be tons of machining that will be done to finish off the project and give it the perfect look. Dash trim, taillights, wheel centers and all of the icing on the cake that will give it a profession touch to match the gorgeous hand built body.

Craftwork Fab is old school, no new technology tooling, a tin man planishing hammer, a bandsaw, break, a bead roller, stomp shear, MIG and TIG welder and that’s it. He’s a firm believer in figuring out problems with the tools you have in front of you and has become very efficient with the tools he has. EJ uses building hotrods as a creative outlet. As EJ puts it, “you don’t make a lot of money on these high end builds,” and, “most people like me are not in this to get rich.”

Huge thank you to EJ for staying at his shop a little late to show me around! You can find EJ on instagram @craftworks__fab__ or on Facebook under Craftworks Fab. Better yet, go visit his shop in Corapolis, PA where you’ll find him beating and shaping metal all day. Last, EJ can be found at many car shows where his work is being displayed and really enjoys talking with everyone at the shows. Can’t wait to see the finished product on the Merc in his shop as well as the Riddler hopeful that will one day be finished!